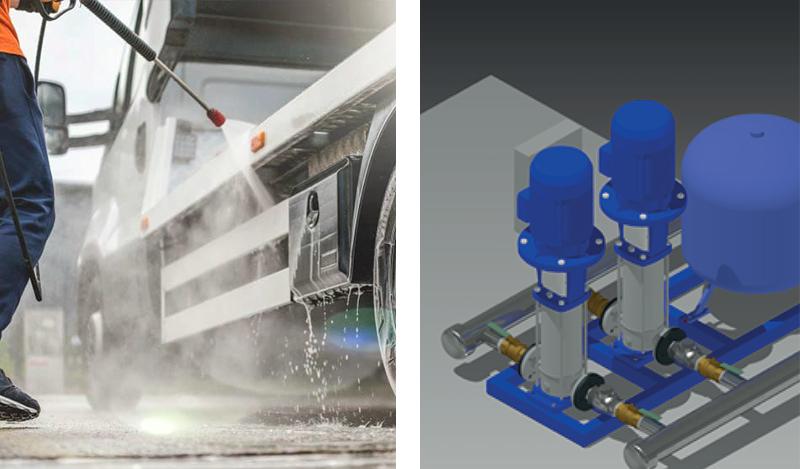

JetWash® is a custom designed heavy-duty solution for Automatic Bus washing system developed based on three pillar-concepts.

1. Proven Mechanism

Suitable combination is made by choosing from various options, viz: Touchless Gantry type system, Automatic washing system with roll over brushes, & Semi- Automatic Bus Wash system customized

for end user requirements.

2. Tylor-made combinations

Our Engineering team is capable to design & supply the modern equipment to cater special requirements of end user & operators’ requirements. The field experience and engineering expertise

of the team ensures optimized system design in a most economical and user-friendly manner. The strategies applied are according to available space & civil structure, water quality, need of limiting water and electricity consumption,

number vehicle per day etc.

3. Long term feasibility

Major parts selected with minimum maintenance requirements by reducing wear & tear elements factors. The frequency of Periodic maintenance at site can be scheduled at minimum level for our

unique designed heavy duty JetWash® systems.

JetWash Customized semi-automatic system allows our customer to define the requirements precisely by adding extra features.

In our standard Semi-Automatic Washing system we provide a drive through water jet washing gantry with

specially designed high pressure nozzles controlled by sensors.

Additional manual wash guns provides an ideal solution for the touch up cleaning required before or after an Automatic Vehicle Wash as per vehicle's condition.

Semi-automatic system allows operator to choose the mandatory features required in the system and allowing to reduce advanced features which may not be required for specific usage of end user.

Drive through Automatic Drying

gantry with powerful blowers is very helpful for quick finishing of bus washing process Any other additional special features from client can also be implemented based on technical evaluation.